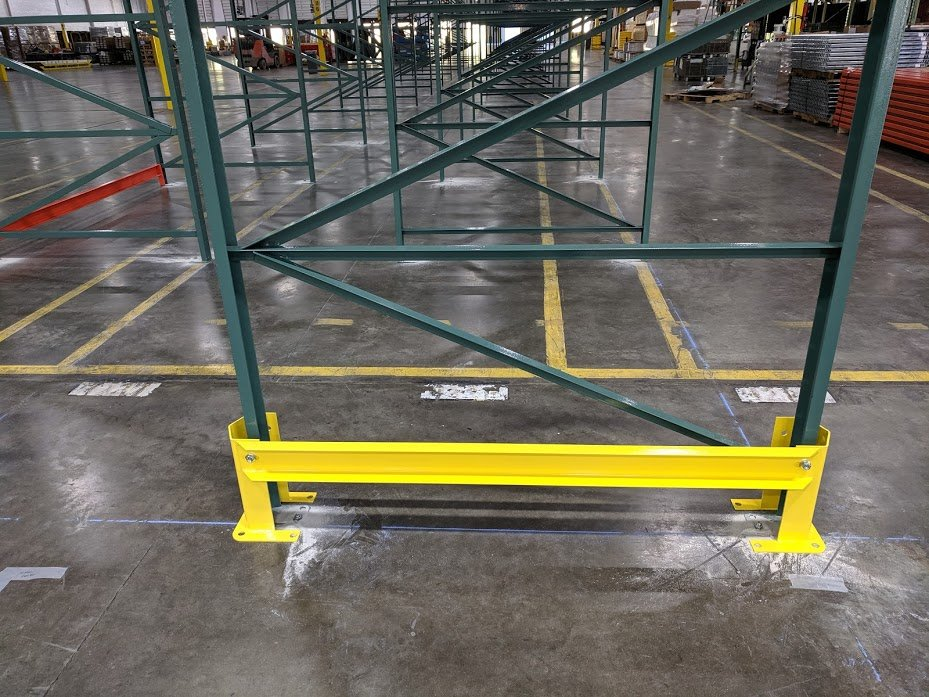

PALLET RACK INSTALLATION

Pallet rack installations are the number one installed material handling project in the warehouse and distribution industry.

Pallet rack installations included static teardrop rack systems, drive in and drive thru racks, push back rack systems, pallet flow rack, structural rack systems, cantilever style racks, and pick modules.

Our crews are available across the continental United States. Professional installation crews meet all OSHA safety regulations, forklift and scissor lift certification, have applicable insurance coverage, and practice industry standard safety measures.

Safety is the number one goal when installing pallet rack.

Installs are performed according to design drawings, with a reasonable time frame to meet project deadlines and within budget.

Key features to pallet rack installations include:

- Securing or unloading pallet rack

- Securing applicable lift equipment on site

- Wearing and utilizing safety equipment

- Working with and around existing personnel and equipment

- Ensuring rack is installed to manufacturers specs and per customer’s drawings

- Adhering to customer’s code of conduct and safety protocol